Aerospace Qualified Solutions

Our solutions reduce cost, weight, and downtime for our customers.

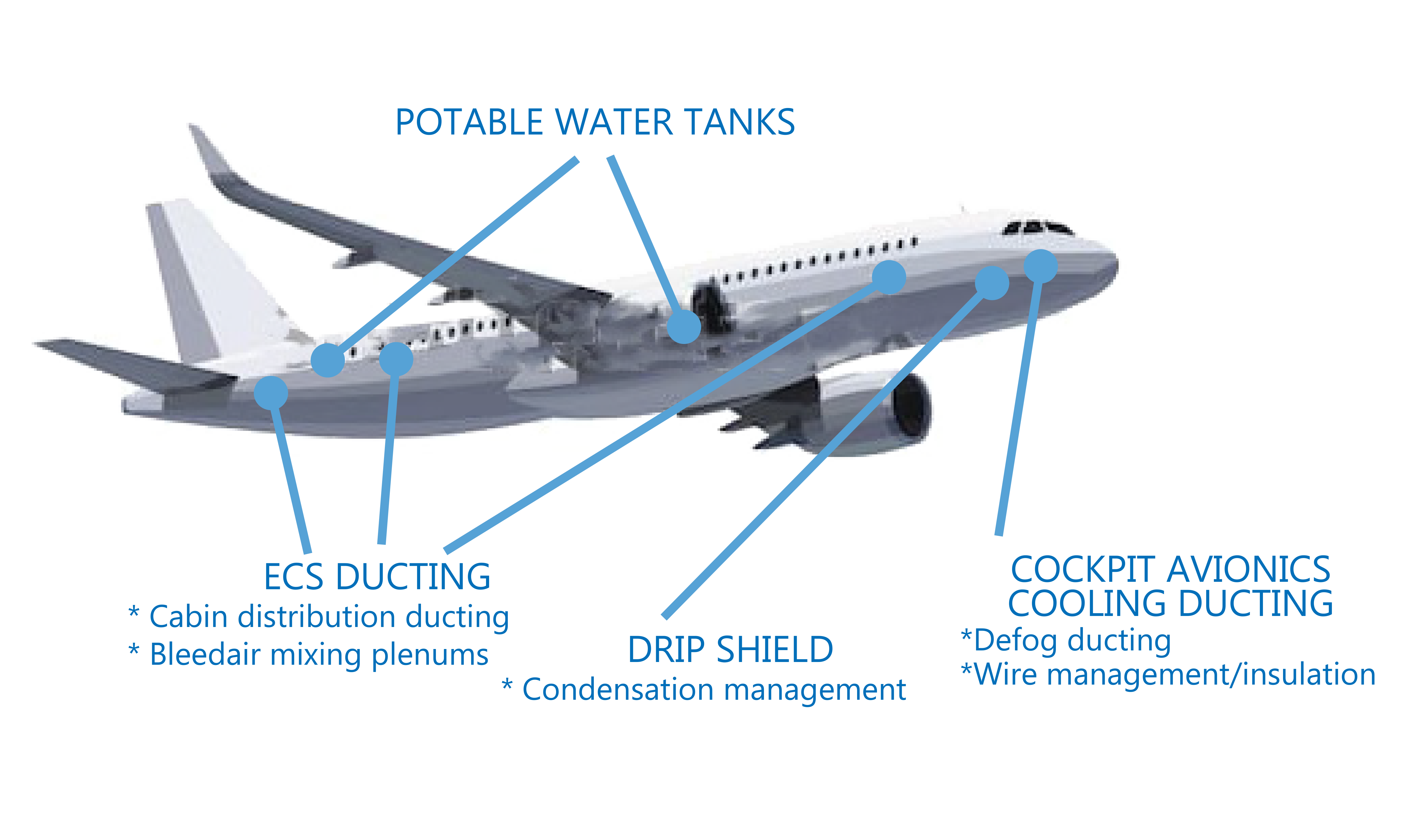

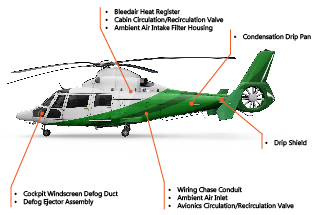

We are experts at manufacturing thermoplastic interior components with complex geometries suited to ECS ducting, tanks, drip pans, and other applications. Our solutions reduce cost, weight, and downtime for our customers. We have been producing aerospace components for the commercial and defense industry since 1972, using rotational molding and additive manufacturing processes.

Content on Existing Platforms

The industries we serve are both commercial and defense aircraft, including helicopters and fixed wing aircraft. If you have a project in mind that you would like quoted, please contact us.

Engineered Resin Formulation

We are also a long-established leader in custom resin formulation for highly specialized applications. Our thermoplastics are processed in-house to ensure quality and consistency. We are able to produce custom formulations for your specific applications in small or large quantities.

Our RMB 437 nylon resin is the only qualified resin applicable for the aerospace rotational molding process per spec BMS 8-270 Type I, Class 4, Form D.

Advantages of Rotational Molded or Laser Sintered Ducts Compared to Composite, Aluminum, or Extruded Ducts:

![]() Lower cost per part

Lower cost per part

![]() Potential for weight reduction

Potential for weight reduction

![]() Supports complex geometries, which reduces part count

Supports complex geometries, which reduces part count

![]() Tooling cost is low or non-existent

Tooling cost is low or non-existent

![]()

![]() Durable parts that withstand impact during installation and maintenance

Durable parts that withstand impact during installation and maintenance

![]() Processes are ideal for aerospace part quantities

Processes are ideal for aerospace part quantities

Disadvantages of Rotational Molded or Laser Sintered Ducts Compared to Composite, Aluminum, or Extruded Ducts:

- Part weight may be more compared to other manufacturing with other processes

- There can be diameter to length restrictions (18” length per 1” diameter)

- There are temperature constraints of the part, due to the process being limited to plastics

What makes our Aerospace Solutions process different?

- Value add services (link to Additional Services page) to save you time and eliminate additional expense

- We can utilize your electronic inventory management systems to maintain on-time deliver

- Proprietary resins, manufactured in-house, are designed to meet OEM flammability, smoke, toxicity, temperature and materials requirements

- Rigorous testing to ensure your product is compliant

- Quality control for your product, operating under ISO 9001-2000 and AS9100:2016

- Short lead times to meet your important deadlines

- Tailored solutions and engineered design to meet your specific needs

- Guidance to help you choose the best material for your application

- Consistent quality that comes from rotationally molding aerospace components for over 30 years

Companies We Work With:

Boeing Commercial Airplanes, Boeing Defense Systems, Triumph Group, Northrop Grumman, Sikorsky Global Helicopters, Sikorsky Military Systems, Bell Helicopter, Lockheed Martin Spirit Aerosystems, Saint Gobain, and others.

Designing for Rotational Lining

Rotational [...]